Sub Surface provide Cable Percussive Boreholes throughout the UK for Geotechnical and Environmental Site Investigations, to provide information and soil parameters on ground conditions and to enable advice to be given on the most suitable Foundation Design for new developments and other Geotechnical and/or Geo-environmental aspects.

Cable Percussive Boreholes are the most common type of boreholes drilled throughout the UK, and can achieve borehole depths of up to 50m using a clay cutter through cohesive soils, a shell through granular soils and a chisel to break up rock and other hard layers.

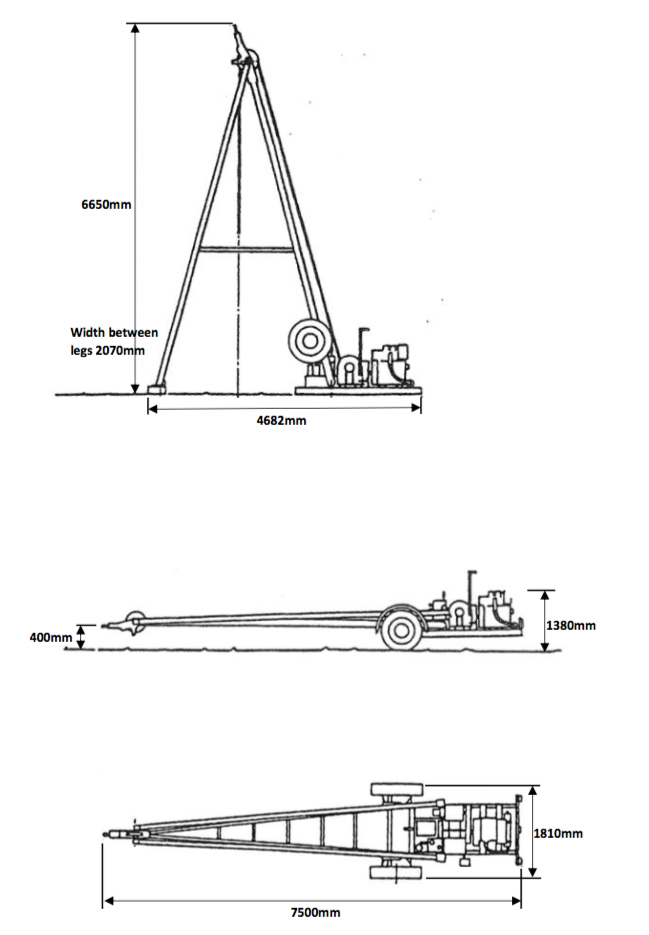

A Cable Percussion drilling rig (aka. Shell and Auger drilling rig) is a mobile tripod rig towed by a 4×4 wheeled drive vehicle. The rig is powered by a diesel engine and requires a working headroom of approximately 6.7m.

Casing allows stability to be maintained within a borehole where loose and water bearing granular soils are present. 150mm (6inch) or 200mm (8inch) diameter casing are generally used, with other larger diameters available upon request.

The ground bearing capacity can be determined within the Cable Percussive Boreholes from Standard Penetrations Tests (SPTs), Cone Penetration Tests (CPTS) and undisturbed U100 samples. In addition, disturbed bulk and jar samples of each strata will be taken for Laboratory Testing, Contamination Testing, and for our Engineers to log in accordance with BS EN ISO 14688-1 and BS EN ISO 14689-1.

On completion, the boreholes are backfilled and reinstated or standpipes can be installed for Gas Monitoring and/or Groundwater Monitoring.

Cable Percussion Drilling Rig Dimensions

The Cable Percussion Rig dimensions are based on a Dando 2000. Dimensions of other drilling rigs which we may use vary and therefore if drilling is to be undertaken within a confined space or an area with restricted access, dimensions should be confirmed prior to arrival on site.

Whom to Contact

If you would like a quote for Cable Percussion Boreholes as part of your Site Investigation or have any questions, please do not hesitate to contact your Regional Sub Surface Office.